Sweeper OVERVIEW

SUPER BROOM – SCM 400 – Self Propelled Sweeper

The SUPER BROOM SCM 400 Self Propelled Sweeper is designed to be the most innovative self propelled sweeper on the market. The features were designed with years of industry experience. From the visibility in the cab to the accessibility and ease of engine maintenance, the SCM 400 self propelled sweeper is an all around valuable asset to road construction projects, including milling operations, road resurfacing, airport runways, and a variety of other construction site needs.

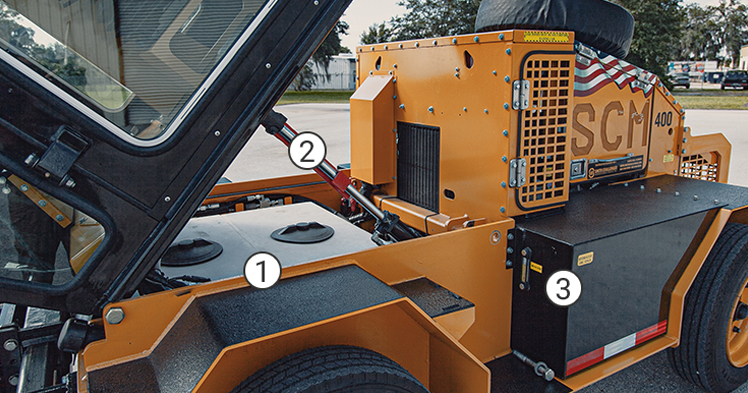

Under the Cab

1) Water Tank – 100 gallon under cab water storage. Consisting of two 50 gallon tanks. Allowing for easy removal. Both tanks are fitted with screen strainers and drain lines. Tanks can be filled at the front of the machine without raising cab. Water system filtration and 12volt pump are accessible at the rear of the machine under the rear access hatch for ease of cleaning.

2) Cab Lift – Hydraulic cab lift. Allowing full access under the cab. Cab lift system has safety features such as a safety bar and PO check valve to prevent cab from falling during maintenance procedures.

3) Hydraulic Oil Tank – 35 gallon Hydraulic oil tank. Consist of external oil/temperature gage. Hydraulic oil filter is replaceable 10 micron filter and easy to access. Dirty filter indicator gage is located on the side of the filter canister. 2 strainer filters are located inside the tank to prevent contaminating debris from entering the hydraulic system.

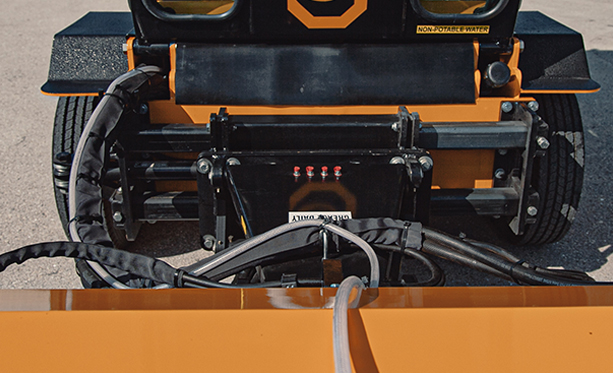

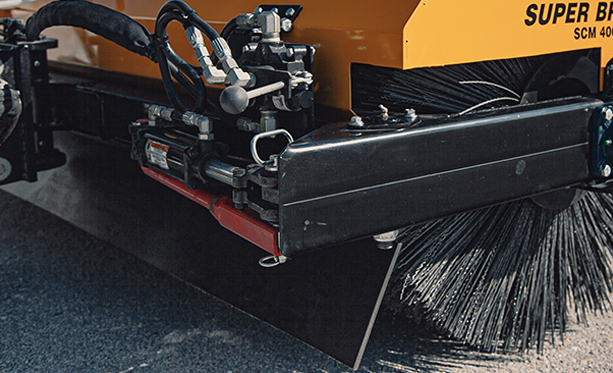

Side Shift

Side shift allows for the broom head to be shifted left or right approx. 11”. This option helps to prevent pre-matured tire failure. Allowing the operator to run the machine away from curbs, retainer walls, milling cuts etc.

Spray Bar

Fold out spray bar allows for water to be sprayed out front of the broom where dust and debris are the heaviest. Spray bar can be folded back and latched down securely when not in use.

Quick Change Arm

Quick change allows the operator to change the broom out, in the field. This requires the use of no tools and can be done in aprox.2 minutes.

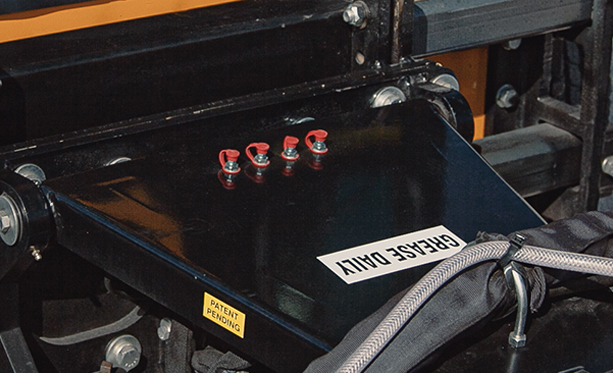

Grease Fitting

Easy access grease point. Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitatio.

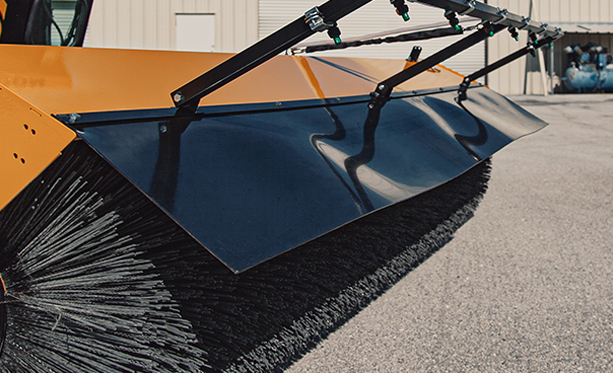

Front Dirt Deflector

The front dirt deflector keeps the dust and debris out front of the machine and as low to the ground as possible.

Rear Dirt Deflector

The rear dirt deflector helps to protect the machine from debris during the need for reverse sweeping. Reverse sweeping is a low rpm function.

Cab Lighting

High output led lighting is located on all four corners of the cab, providing high visibility during low light operations.

Wheel & Tire

Heavy Duty wheels and tires. Custom made to be interchangeable at all four wheel locations. Tires are steel cased to extend tire life.

Around the Back

1) Rear Bumper – Heavy Duty rear bumper helps to prevent damage to the transmission Compartment and overall rear of the machine.

2) Fresh Air – The fresh air system provides the cleanest air possible into the cab ac system. Allowing for the most efficient operation. Also keeps the cab pressurized to help prevent dust particles from entering the cab area.

3) Spare Tire – Heavy Duty matching spare tire and wheel, mountable on all four locations of the machine.

4) Tie Down – Heavy D ring tie downs are located on all four corners of the machine, for safe and secure transport.

5) Fuel Tank – 35 gallon fuel tank allows for long run time between fueling. Machine has in cab fuel indicator along with a fuel level gage located next to the fuel fill spout to help prevent overfilling.

6) Rear Flashing Lights – Constant rear flashing lights provide visibility of the machine during operation.

Rear Hatch

Rear hatch door allows access to the hydraulic pumps, charge filter, water system pump and filter. This allows maintenance to be done with ease.

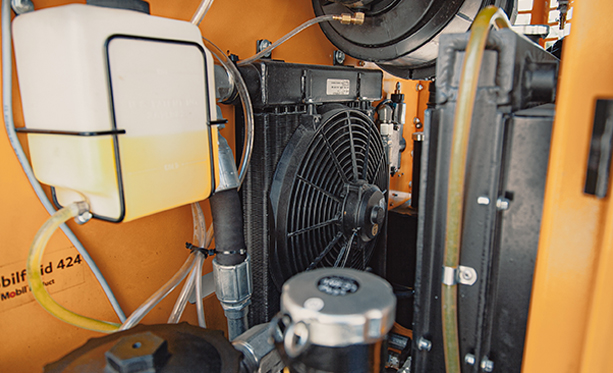

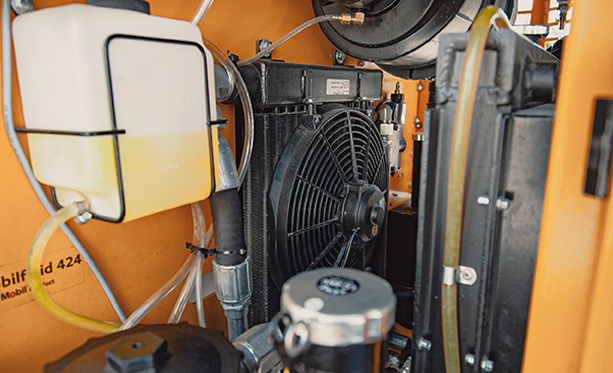

Side Hatch Door

Side hatch doors allow access to engine, radiator, oil cooler, engine air filter etc. All hatch doors are lockable.

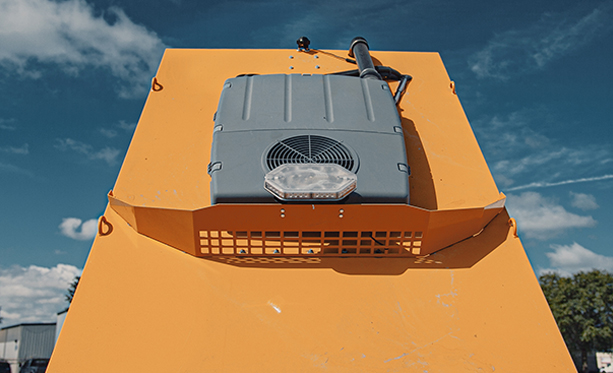

Roof Air Conditioner

Red Dot roof mounted AC/Heating system. Force fed system allowing for the most efficient climate control possible.

Rearview Camera

Rearview Camera assist the operator with rear visibility of the machine during operation.

In the Cab

1) Fuse Panel – Accessible to the operator from the cab seat.

2) Windshield Wiper – Panoramic windshield wiper provides wide visibility during harsh conditions in cab water reservoir for easy access.

3) Left Control Panel – Control panel with noted control functions. Arms reach access to the operator.

Joystick

Joystick operation for all broom, machine speed and horn functions. Includes control function decal on the front windshield, visible from the seat, for operator assistance when needed.

In-Cab Pressure Gauge

In-Cab pressure gages for operator to monitor the system pressures at all time.

Rops Certification

Rops certification/Vin plate.

Emergency Brake Release.

Emergency brake release allows the operator to release the hydraulic brakes manually for tow ability.

Right Hand Control Panel

Left Engine control screen allows for custom arrangement of engine gages and control ability. Right Rpm screen and indicator lights shows the operation of the broom. (forward,reverse and rpm of the broom).

Learn how The Smith Challenger Line of Sweepers

can increase productivity and eliminate downtime.

Faster, more accurate and more economical than traditional sweepers.